End grain connections outdoors

End grain connections outdoors

Why are end grain connectors not suitable for service class 3?

Modern timber construction stands for precision, prefabrication, and efficiency. Despite all the innovations in this field, one principle remains unchanged: connections using end grain are and remain a challenge in timber construction—especially when exposed to the elements. The following section examines why wood connectors in service class 3 are problematic and what options are available to avoid this issue.

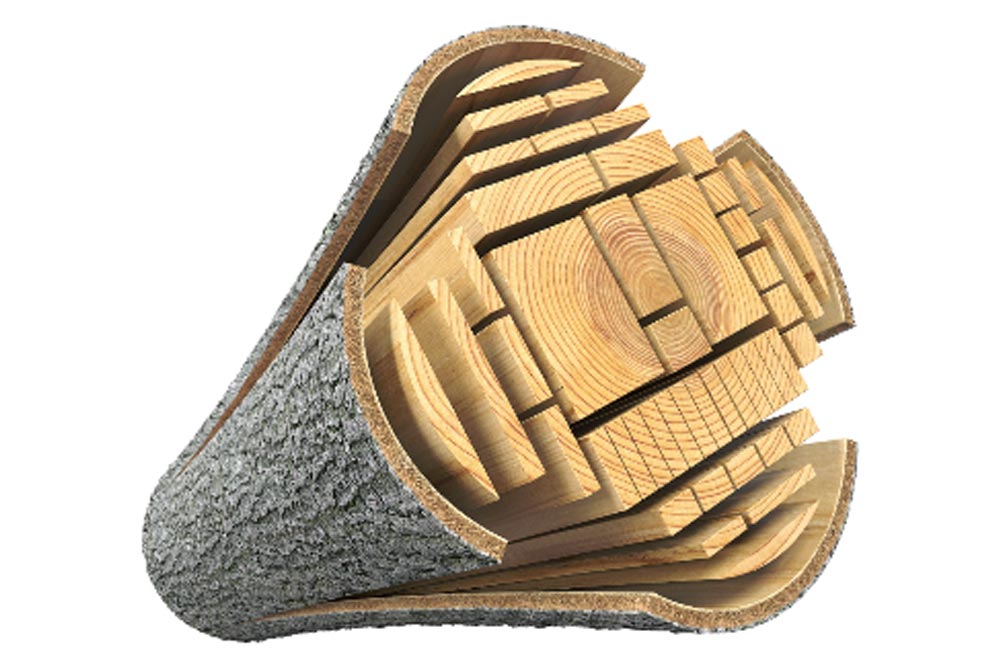

What is end grain?

End grain (also known as cross grain) is created when wood is cut across the grain, i.e., perpendicular to the longitudinal axis of the tree trunk. This exposes the cross-sections of the wood fibers. Typically, the wood is cut and arranged so that the annual rings are visible from above. This arrangement creates a characteristic circular pattern. Due to its resistant surface, end grain wood is often used for cutting boards.

What are its properties?

End grain wood has a number of characteristic properties that make it particularly suitable for certain applications. However, it also has clear limitations in other areas. One positive feature is its exceptionally high compressive strength in the grain direction, which makes the wood suitable for heavily used surfaces such as workshop floors, gyms, or industrial areas.

End grain wood is also popular for indoor use, for example in cutting boards or kitchen worktops: the vertical fibers tend to close temporarily when exposed to moisture, which supports the natural antibacterial effect. In addition, it has good regenerative properties — end grain wood surfaces can be easily sanded down and resealed, so with proper care they can last for many years.

Problems with end grain

However, this particular type of wood cut also has significant weaknesses, especially with regard to moisture. The surface runs perpendicular to the grain, exposing the cell structure and allowing water to penetrate deep into the wood unhindered. Without suitable structural wood protection, this promotes the growth of wood-destroying fungi and decay processes, especially where there is little air circulation.

In addition, end grain has a significantly lower pull-out strength for fasteners than longitudinal grain, which makes it problematic for load-bearing connections—particularly when exposed to the weather.

While end grain wood is impressive in interior applications thanks to its functionality, hygiene and durability, it should only be used in load-bearing timber construction, especially in use class 3, with effective moisture protection or not at all.

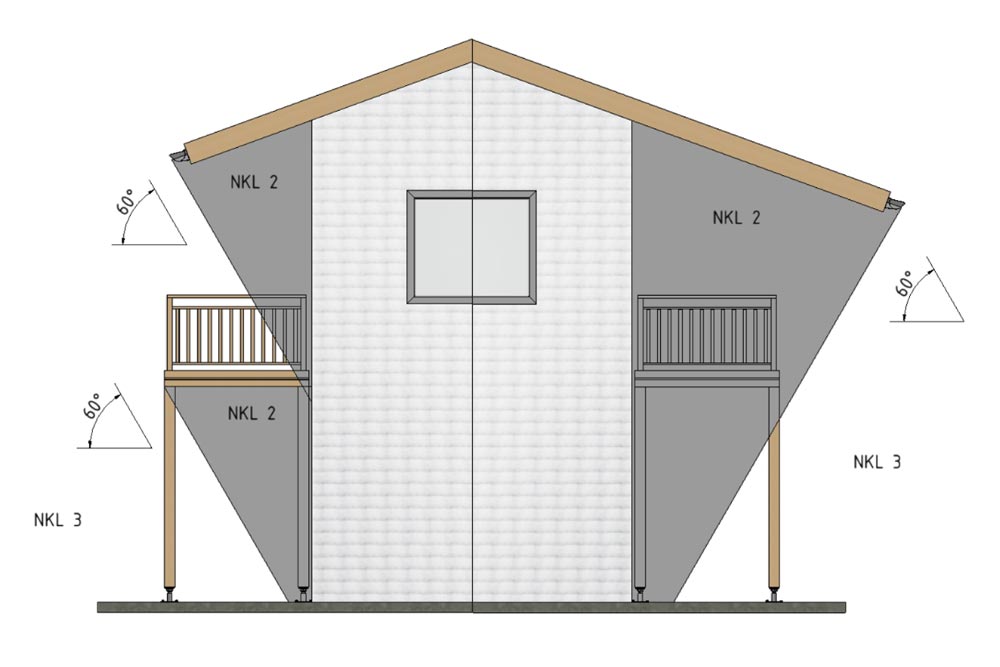

Service classes in timber construction according to DIN EN 1995-1-1

The service classes (NKL) define the environmental conditions under which timber structures or components are used. Ultimately, the service class is decisive for the design of timber components, timber protection and, finally, for the selection of suitable fasteners.

Service class (SC) 1 → u = 10 ±5 %, usually ≤ 12 %

Wood equilibrium moisture content 5 to 15%, usually not > 12%, corresponding to a temperature of 20 °C and a relative humidity of the surrounding air that only exceeds 65% for a few weeks per year

Example: heated interiors, living spaces, offices

Service class (SC) 2 → u = 15 ±5 %, usually ≤ 20 %

Wood equilibrium moisture content: 10 to 20%, corresponding to a temperature of 20 °C and a relative humidity of the surrounding air that exceeds 85% only for a few weeks per year.

Example: outdoors, but roofed or protected from direct weather exposure.

Service class (SC) 3 → u = 18 ±6 % → for example, a wooden terrace

Wood equilibrium moisture content: 12 to 24%, corresponding to climatic conditions that result in higher wood moisture levels than those specified for Service Class 2.

Example: wooden decks, façades, timber structures without roof overhangs, carports, playground equipment.

Why do end grain connectors fail in service class 3?

Our product range includes a wide selection of wood connectors and fasteners developed for various applications in structural timber construction. Particularly in load-bearing connections, the fasteners must be selected in accordance with the respective service class. The available systems include the Atlas wood connector, Magnus hook-in connector, IdeeFix wood connector, and KonstruX fully threaded screws in A4 stainless steel when used as screw crosses.

Fasteners must always be approved and suitable for the respective usage class. What works reliably in service class 1 may fail in service class 3 due to increased moisture exposure.

Examples of Equilibrium Moisture Content:

-

Living tree → up to 150%

-

Fiber saturation (depending on wood species) → 25 to 35%

-

Wooden window frames → 12 to 15%

-

Indoor areas (stove-heated) → 8 to 10%

-

Indoor areas (centrally heated) → 6 to 8%

-

Floors, parquet → 5 to 13%

-

Oven-dry (technically achievable only) → 0%

Examples of Installation Moisture Content:

-

Timber structures → max. 18%

-

Floors (interior) → max. 12%

-

Stairs → 9 ±3%

-

Decking/timber terraces → 16 ±2%, max. 20%

The durability of a wood connection depends not only on the material of the connector or screws but above all on the structural wood protection. Particularly in the case of unprotected end grain connections, wood-destroying organisms, especially fungi, find ideal conditions for settling in the end grain of the connected component (e.g., secondary beam). In addition, depending on the connector selected, such connections often lack sufficient ventilation.

The result is permanently increased wood moisture in the connection area, which promotes the decomposition process of the wood. This can lead to a significant loss of strength — for example, through transverse tensile failure or loss of the pull-out resistance of the screws, meaning that the load-bearing capacity of the connection is no longer guaranteed. At the same time, the humid environment increases the risk of corrosion of the fasteners, especially when using standard steel.

A large number of wood connectors available on the market are only approved for service classes 1 and 2.

What alternatives are there for service class 3?

Most end grain connectors approved by building authorities are only approved for service classes 1 and 2 (dry or moderately humid environments).

Wood connectors are generally only permitted in service class 3 if the wooden structure is designed in such a way that the typical conditions of this use class are significantly reduced by suitable structural measures. Effective structural wood protection and technical adjustments to the connection details are crucial for this. The following methods can be used:

1. Reduction of moisture stress through structural wood protection

If the end grain can be protected so that it is no longer exposed to direct or constant moisture, the connection can also be classified in a lower service class.

- Complete coverage of the end grain surface, e.g., with sheet metal

- Use of corrosion-resistant materials, e.g., A4 stainless steel

- Good ventilation to allow the wood to dry

2. Use of approved connectors

Some manufacturers offer special wood connectors or screws for load-bearing structures that are explicitly approved for service class 3. The prerequisites for this are:

- A European Technical Assessment (ETA) or General Building Approval (abZ), technical reports, usability certificates, or similar

- Corrosion-resistant material, e.g., A4 stainless steel

End grain connectors in service class 3 – only permitted with approval and appropriate protection

The use of end grain connectors in service class 3 is only possible under certain conditions — namely, if the structure is specifically protected against moisture penetration.

Effective structural wood protection, for example through covers, ventilation, and suitable measures for water drainage, as well as the use of fasteners approved for this type of stress, are crucial. Equally important is standard-compliant execution in accordance with the specifications of the respective manufacturer.

If these protective measures are not taken, there is an increased risk of moisture damage, loss of strength, and thus possible failure of the connection.

Do you still have any technical questions?

We’ll be happy to advise you on your construction project!

Create a ticket now so we can help you quickly and efficiently — or use our free calculation software for your planning.

Other technical articles

Here you’ll find information and news about Eurotec.

Discover new catalogues, products, and other topics.

Deutsch

Deutsch  English

English  Dansk

Dansk  Español

Español  Italiano

Italiano  Français

Français  русский

русский  Polski

Polski