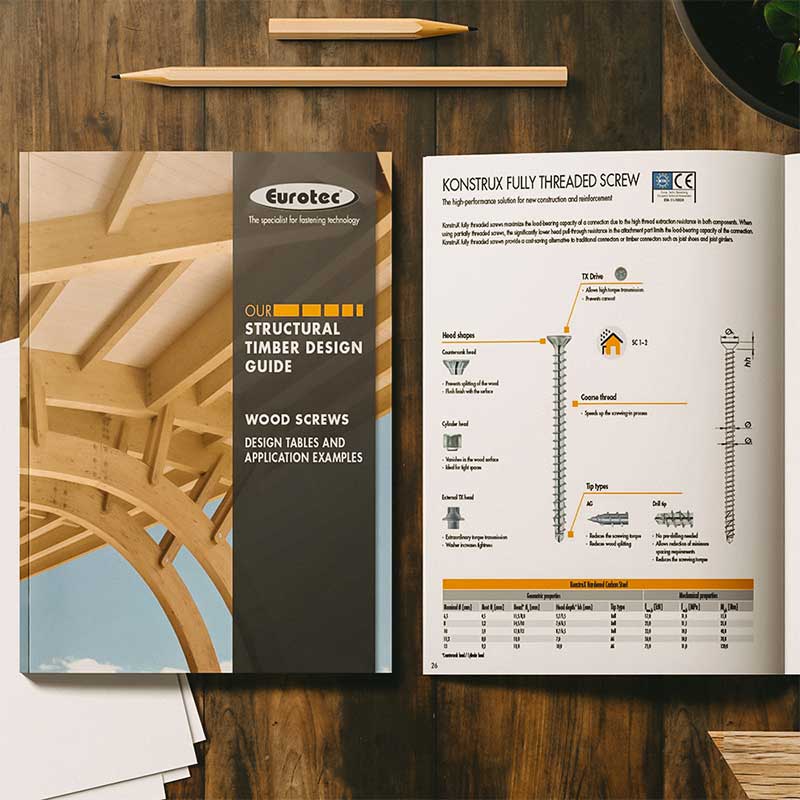

KonstruX fully threaded screws – maximum load capacity for your timber construction

Load capacity and planning of self-drilling wood screws

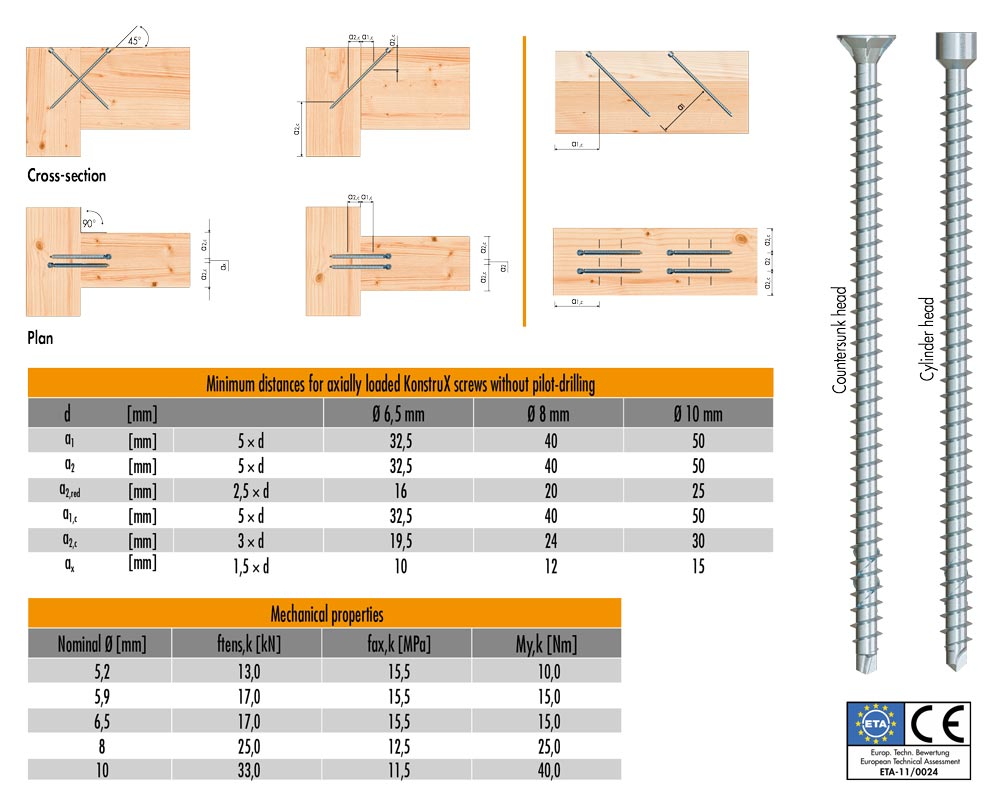

When designing self-drilling wood screws, engineers must ensure that there is sufficient net wood area for load transfer between the timber elements.

In the case of a laterally loaded connection, equations for the stretching strength predict the load-bearing capacity of a bolt, taking into account various types of failure. However, predictions are only valid as long as premature brittle failure modes such as group breakaways are prevented. In addition, the requirements for edge and center distances must be met to avoid splitting and cracking during installation.

Influencing parameters are as follows:

- Screw diameter

- Screw tip: drill bit, AG tip, etc.

- Installation angle and contact surface

- Loads: shear force, axial loads

Here, when installing screws, our rBS drill bits help to reduce internal wood tension by removing material instead of crushing wood around the thread. Even if screws are not pre-drilled on site, their clearance rules are considered pre-drilled according to ETA-11/0024.

KonstruX fully threaded screws: features and performance

KonstruX fully threaded screws are mainly equipped with a drill tip. Thus, their distance rules for EC-5 are considered pre-drilled, even if the components are not pre-drilled. According to ETA-11/0024, the minimum distances can be reduced. Thus, more screws can be used in a small area to achieve a higher load capacity.

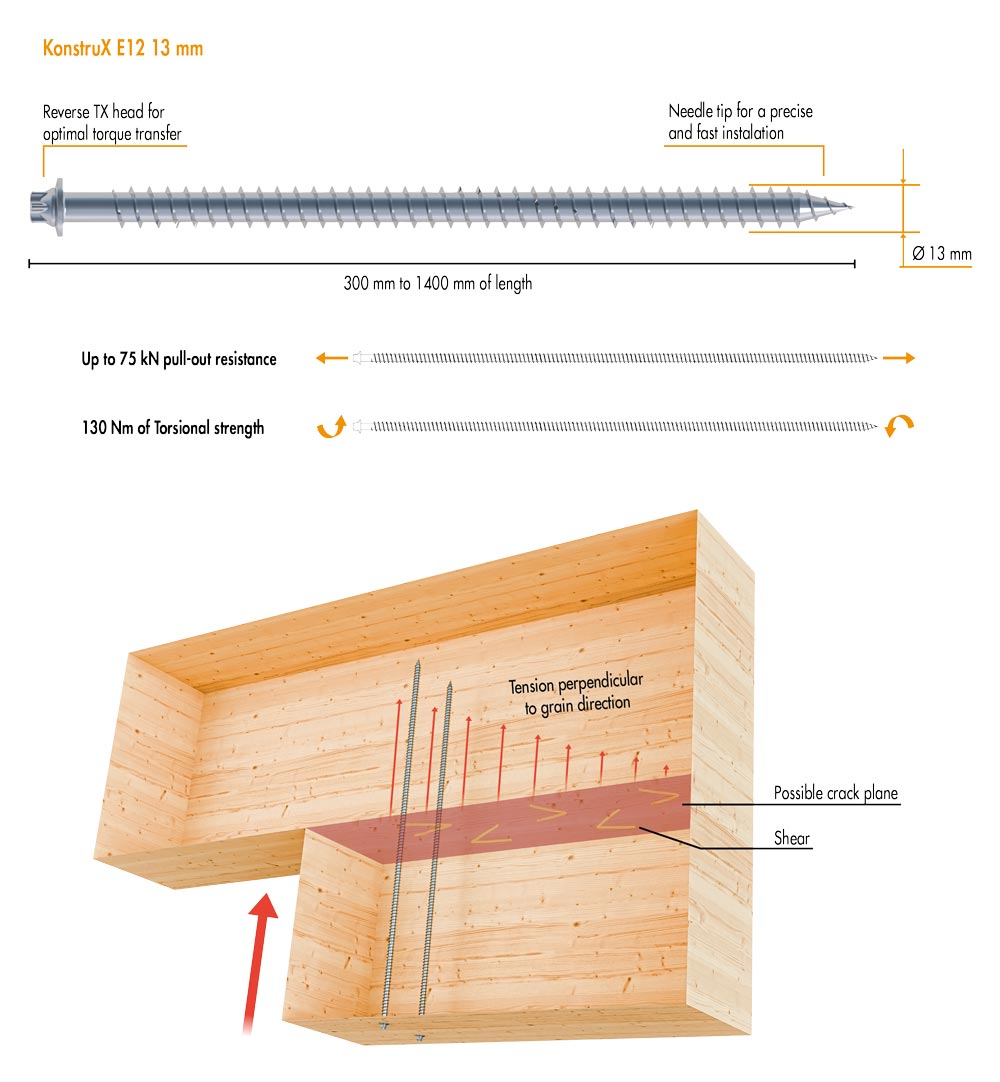

Maximum performance with the KonstruX 13 mm E12

The KonstruX 13 mm E12 fully threaded screw – the most powerful member of the range of self-drilling timber construction screws. With a coarse full thread over the entire length and an outer diameter of 13 mm, this screw is specially designed for excellent axial pull-out strength in wooden components.

Their impressive tensile strength of 75 kN allows full use of the maximum screw length of 1400 mm, making them particularly suitable for large projects.

Typical applications include torn or cracked glulam beams, as well as reinforcing beams and joints to increase load-bearing capacity and reduce long-term deformation.

Installation guidelines

Since pre-drilling is generally recommended for screws with such an extraordinary length – due to the high probability of deviating from the intended direction when screwing in – a drill tip would be unnecessary in these cases. Instead, a regular screw tip is used to ensure quick and precise assembly. The torsional strength of 130Nm of the KonstruX 13mm E12 also ensures a safe screwing experience.

We recommend pre-drilling one third of the length of the 13mm E12 KonstruX with a diameter of 9mm in order to reliably implement the planned construction.

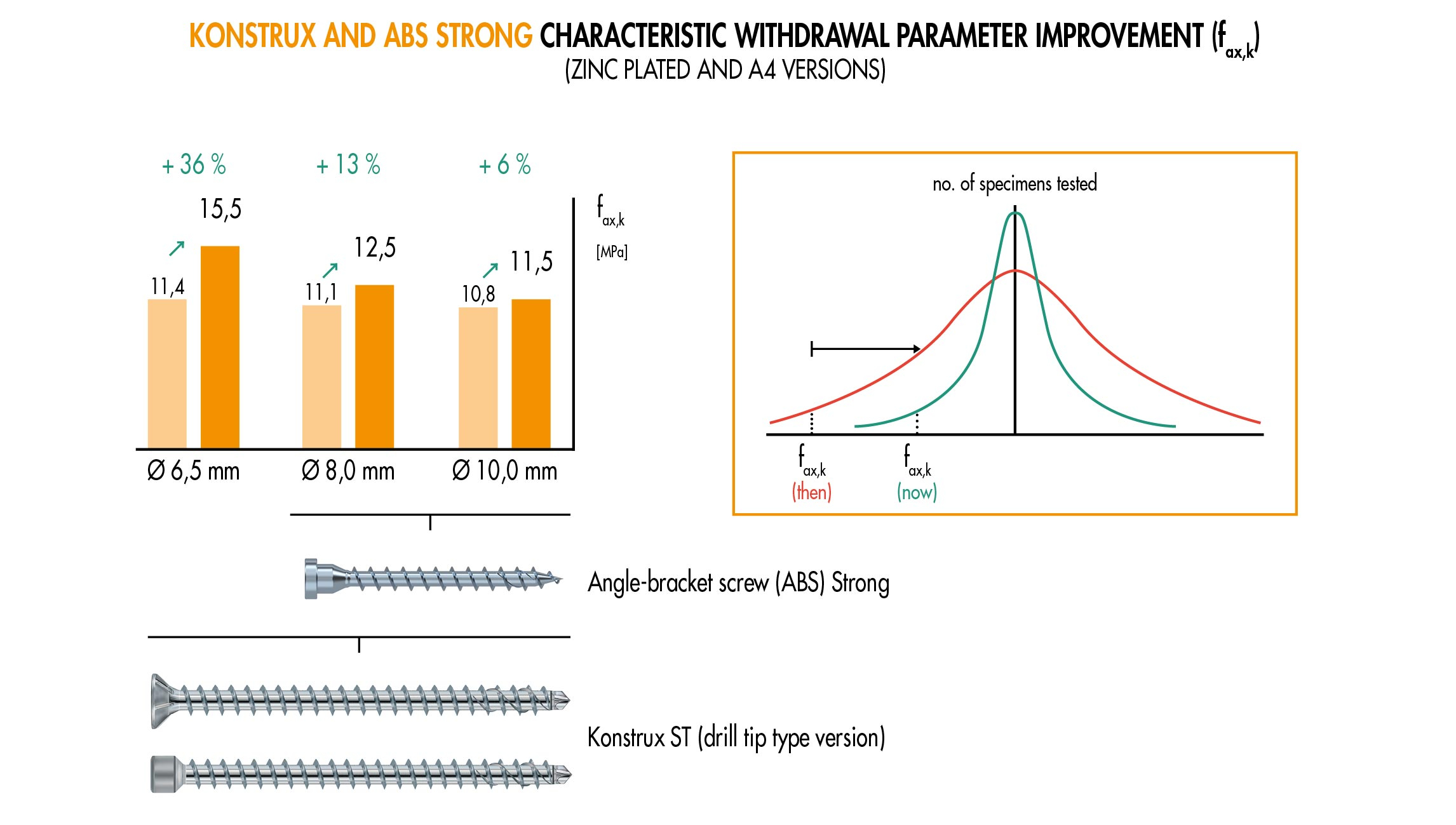

ETA certification: Updates and benefits

After completing an extensive test program, the ETA certificate 11/0024 for our wood screws has been officially updated.

This means that the latest screws meet the technical requirements for the European market and the classic fully threaded screws are even more powerful.

The main updates:

- Up to 36% higher characteristic pull-out parameters of the KonstruX and Strong Angle Fitting Screw (both galvanized and A4).

- New smaller diameters for KonstruX screws: ø 5.2 mm and ø 5.9 mm.

- Taurus 45° washers are now certified, in addition to new sizes of construction ø 6.5 mm.

- Paneltwistec A2 disc head ø 3.5 mm to ø 6 mm.

- Angle Fitting Screws (WBS) A4

- Recording of the method of beam thrust reinforcement with screws and threaded rods.

- The length limit for Paneltwistec Ø 12 mm has been increased from 400 mm to 600 mm.

The new KonstruX small diameter screws are a direct response to the market demand for a strong, fully threaded screw that meets the minimum geometry requirements when using slender wood components.

Reducing the variability of the tested values allowed for a natural increase in fax,k parameters closer to their true strength value, ensuring stronger connections according to certification with the same number of common screws.

Ductility and earthquake safety

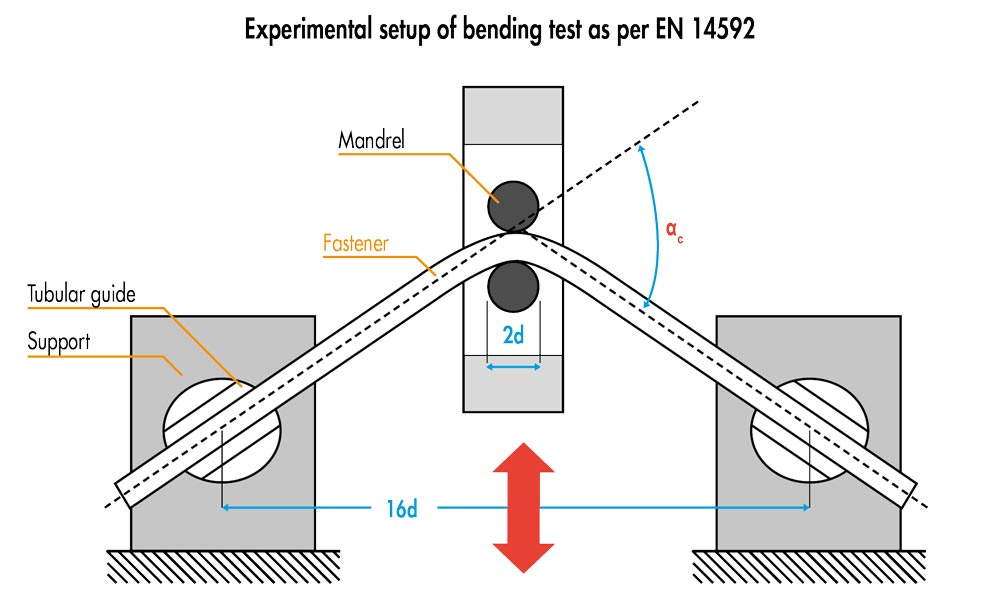

In earthquake-prone regions, building codes require designers to consider the impact of seismic events on the structure. In the case of timber structures, this means that the connections between the building elements must withstand high-frequency, alternating shear loads.

Self-drilling screws are indispensable in timber construction – from light to heavy cross-laminated timber (CLT). Partially threaded screws in particular are often used in grooved or overlapped joints to absorb horizontal forces. Therefore, both ductility and structural integrity must be ensured by repeated plastic deformation of the metallic fasteners under seismic loading.

Based on a comparison between monotonic and fully reversing cyclic bending tests, the EN 14592 standard defines three ductility classes that reflect increasing structural requirements (S1 - low ductility class, S2 - medium ductility class and S3 - high ductility class).

A bolt meets the requirements of a class if two criteria are met:

- The residual torque at the end of the cyclic test is at least 80% of the average flow moment from the monotonic test.

- The maximum bending angle defined for the class is achieved without the screw breaking.

Conclusion: Precise installation and verified strength for modern timber constructions with KonstruX

The KonstruX fully threaded screws provide a powerful and reliable solution for load-bearing timber structures. Their continuous full thread and optional drill tip allow for precise installation while reducing internal wood stresses, enhancing the stability of the connection. The updated ETA Certification 11/0024 and verified S3 ductility class ensure maximum load capacity, safety, and durability even under demanding loads and in earthquake-prone regions.

With versatile diameters and lengths, these screws can be flexibly applied in a wide range of components—from slender timber beams to large-scale glulam or CLT constructions. With KonstruX full-thread screws, planners and installers benefit from efficient assembly, verified performance, and maximum planning security, making them a long-term reliable connection solution for modern timber projects.

Calculate your timber projects easily

Use our ECS design software to calculate your timber connections quickly and reliably. Start your project planning today and obtain precise results for load capacity, screw selection, and installation safety.

Optimize your timber connections with proper screwing

Accurate screwing is crucial for the load capacity and safety of your timber connections. Read the technical article to get detailed information on correct planning, installation, and screw selection—for safe, durable, and high-performance timber connections.

Do you still have any technical questions?

We’ll be happy to advise you on your construction project!

Create a ticket now so we can help you quickly and efficiently — or use our free calculation software for your planning.

Other technical articles

Here you’ll find more technical articles with comprehensive content you need to know on the construction site or for individual projects—whether you’re just getting started or already have years of experience.

Deutsch

Deutsch  English

English  Dansk

Dansk  Español

Español  Italiano

Italiano  Français

Français  русский

русский  Polski

Polski